Application

To investigate whether the thermochromic phase change behavior of polydiacetylene thin films will be altered when placed onto a carbon substrate such as graphene, a researcher developed a transfer heat block whose temperature could be regulated over time with a high degree of accuracy. The system allowed the researcher to conduct visual observations while simultaneously performing Raman spectroscopy and UV-Vis reflectance spectroscopy upon the sample.

OMEGA products used in this application

Products

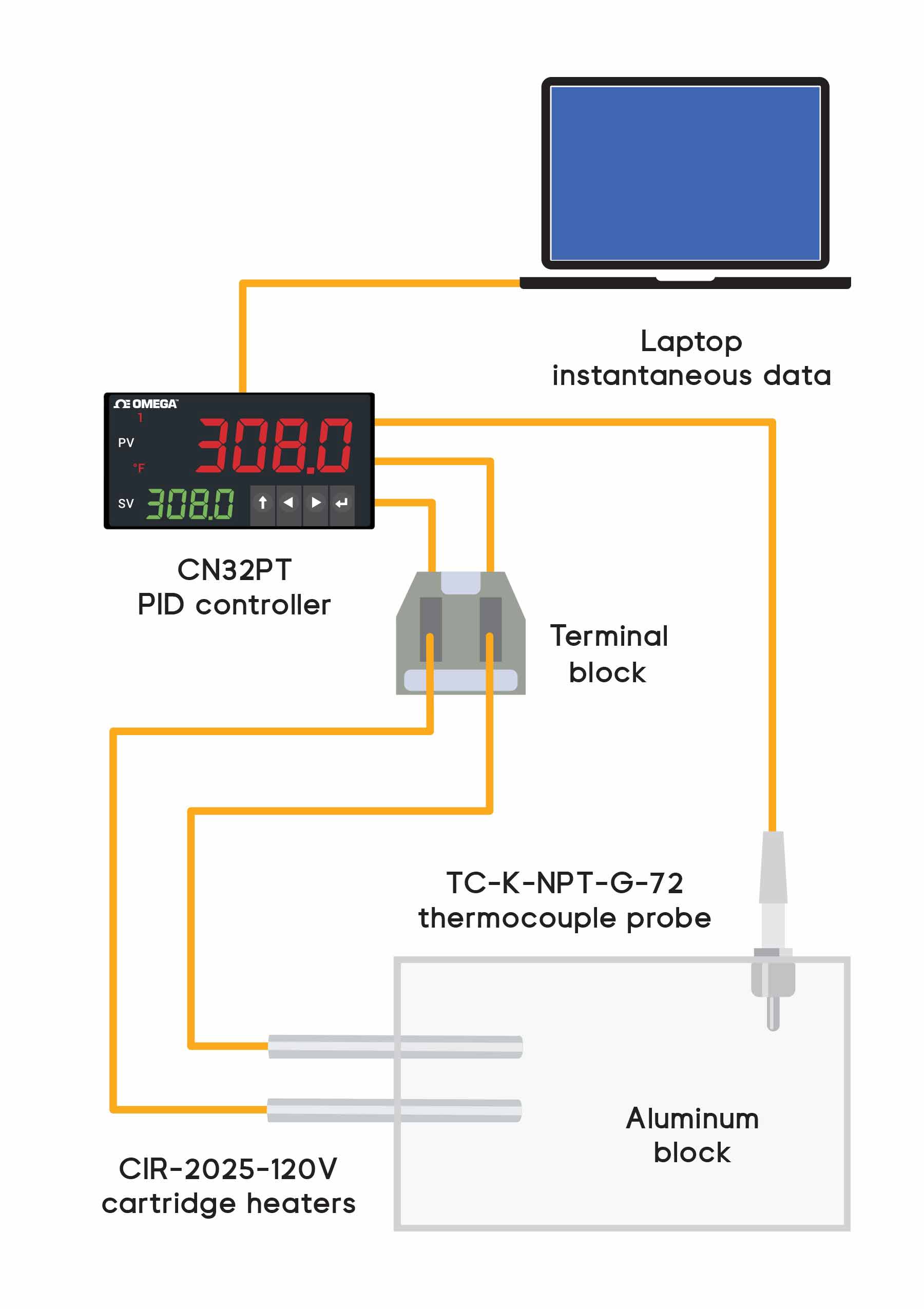

The figure above shows the schematic of the PID-controlled heat source. The application includes three OMEGA products, a plastic casing, high-temperature insulation, an aluminum block, high-heat epoxy, a power cord, wiring connectors, an electronics enclosure box, and high-heat enamel paint:

CN32PT-330: A microprocessor-based proportional-integral-derivative (PID) controller accepting input from thermocouples, RTDs, thermistors, DC voltage, DC current, or strain bridge input types. Control can be achieved through an on/off or heat/cool PID strategy. The device features a three-color programmable display. Various configurations of mechanical relay, SSR, DC pulse, and analog voltage or current outputs are available.

CIR-2025-120V: This rugged, shock- and vibration-resistant, high-density cartridge heater is designed for use in applications involving molds, dies, platens, hot plates, and sealing operations. It features an Incoloy® sheath for improved thermal conductivity that can operate at working temperatures up to 760ºC (1400ºF) with sheath temperatures up to 870ºC (1600ºF) with type K leads. Two 75 W cartridge heaters were employed in this application.

TC-K-NPT-G-72: This thermocouple is fiberglass insulated with a stainless steel over braided and stripped leads. Its rugged pipe plug-style thermocouple probe when equipped with an exposed junction is perfectly suited for air temperature measurement and gas stream monitoring.

How it Works

- Drill holes into the aluminum block to create a recess into which to insert the cartridge heaters.

- Insert cartridge heaters into the aluminum block, and seal them into place with epoxy to create a transfer heat block.

- Thread the aluminum transfer heat block, and screw the thermocouple into it.

- Situate the transfer heat block within the plastic casing and surround it with high-temperature insulation.

- Apply high-heat enamel paint to the heat block assembly to aid with visual observations of the sample.

- Situate the sample atop the heat block.

- Connect the leads from both cartridge heaters and the thermocouple to the PID controller.

- Situate the entire assembly within the spectroscope’s sample area.

- Download PID controller software from the Omega website.

- Connect the PID controller to the PC running the controller software via USB cable.

- Program the PID controller to increase temperature at appropriate intervals until the phase change is observed.

Results

The transfer heat block system was able to increase the sample’s temperature at five-degree intervals with an acceptable level of accuracy until the phase change was observed visually and measured via spectroscopy. This allowed the researcher to accurately determine the temperature at which the phase change occurred.

Pro Tip

Make sure all necessary devices are calibrated properly before use to ensure maximum accuracy in the reading of the system.