Application

In a process application, such as soaking wood in a water bath, unpleasant odors can be omitted. By neutralizing pH levels in the water bath, odors can be controlled. This process can be automated using a pH probe and transmitter to monitor pH levels continually.

In this specific application, the manufacturer was previously using a manual, labor-intensive process of using pH strips to test pH levels and add soda ash to bring pH levels up to neutral. The manufacturer was also unaware that temperature could impact pH readings. The strips they were using were meant to be used in ambient conditions and were likely providing falsely high pH readings.

OMEGA products used in this application

Products

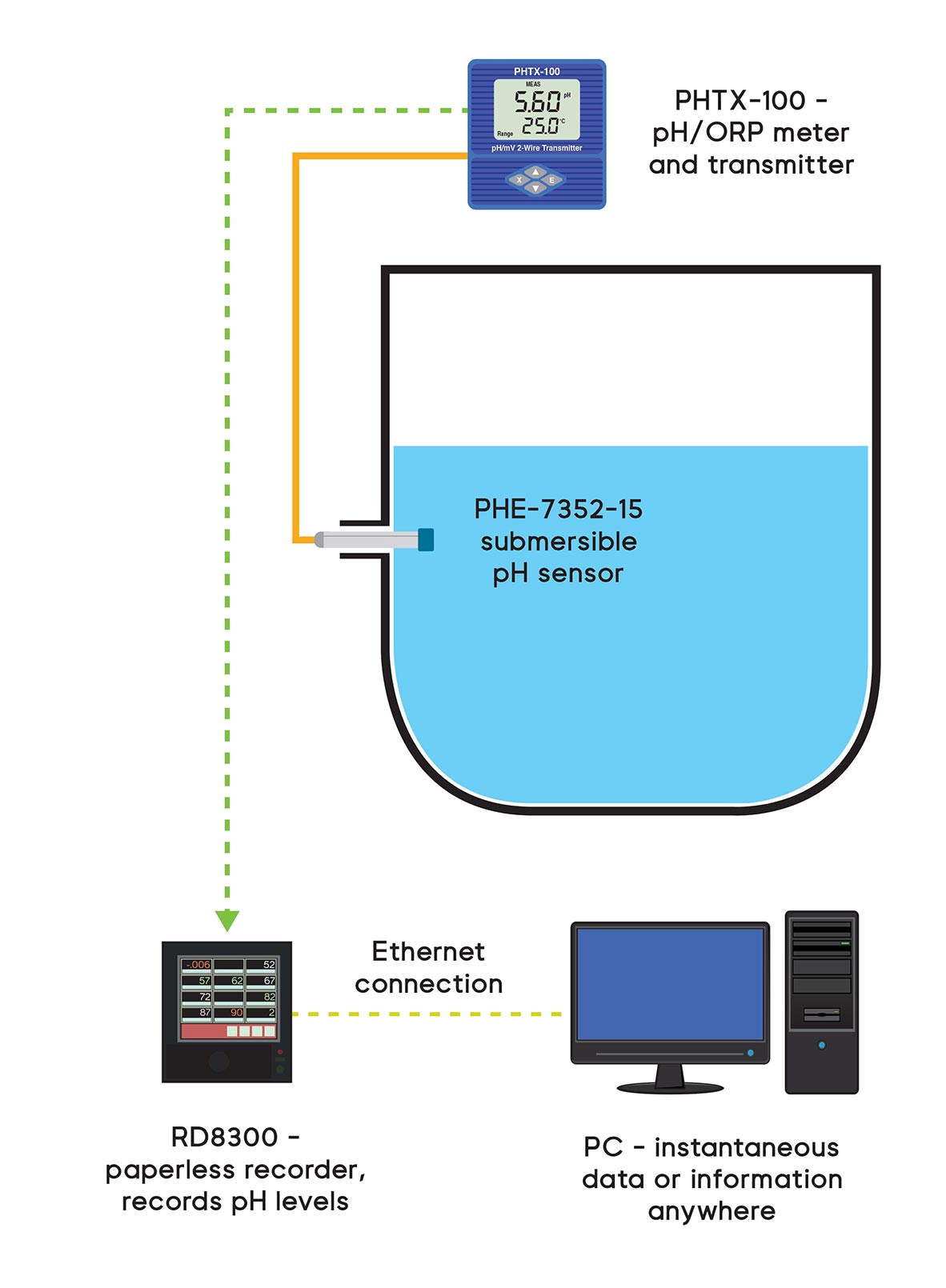

The figure above shows the schematic of the pH monitoring system. The application is comprised of two products:

PHTX-100: This transmitter is a loop-powered 4 to 20 mA output in pH or mV units and has 500V input to output isolation. Temperature is always displayed and is selectable in ºC or ºF. All stored parameters and calibration data are retained in the non-volatile memory during transmitter power down.

PHE-7352-15-PT1K: This pH sensor is designed for insertable use in process and waste water applications where greater pipeline penetration is required. Use of the high-temperature version is recommended where service temperatures continuously exceed 80°C (176°F).

How it Works

- The high-temperature pH probe is mounted on the side of the process tank below the water line to ensure the probe always remains wet.

- The probe is wired to a transmitter.

- The probe continually measures pH levels and transmits the data to the transmitter.

- The transmitter displays as a 40ml amp output, allowing data to be viewed on any data acquisition device or any building management system.

Results

The manufacturer saved time by eliminating the previous labor-intensive, manual process of measuring pH levels. The pH readings were also more accurate due to using a pH probe with temperature compensation. Finally, the addition of continuous, real-time monitoring, enabled the manufacturer to be more responsive to pH levels, add accurate amounts of soda ash, and better maintain a neutral odor.

Pro Tip

Temperature plays a significant role in pH measurements. As the temperature increases, pH will drop. Thus, a pH value without a temperature value is meaningless. To accurately determine pH levels, testing pH must be done on site at the source of the sample with a pH probe with temperature compensation.