Application

Measuring bending stress requires determining the average amount of force exerted on the material that results in a repeatable uniform surface. Load cells can provide an accurate and responsive method for measuring small load increments, a critical component for determining the appropriate level of force for repeatable results.

The load cell should be placed on the roller arm. As the bendable material, such as sheet metal, passes through the machine’s rollers, the rocker arm will apply a force to bend the material. The load cells will measure the force applied.

While this application was specifically designed for measuring the bending force of a sheet metal bending machine, it could apply to other similarly bendable materials such as laminates, glass, or plastics.

OMEGA products used in this application

Products

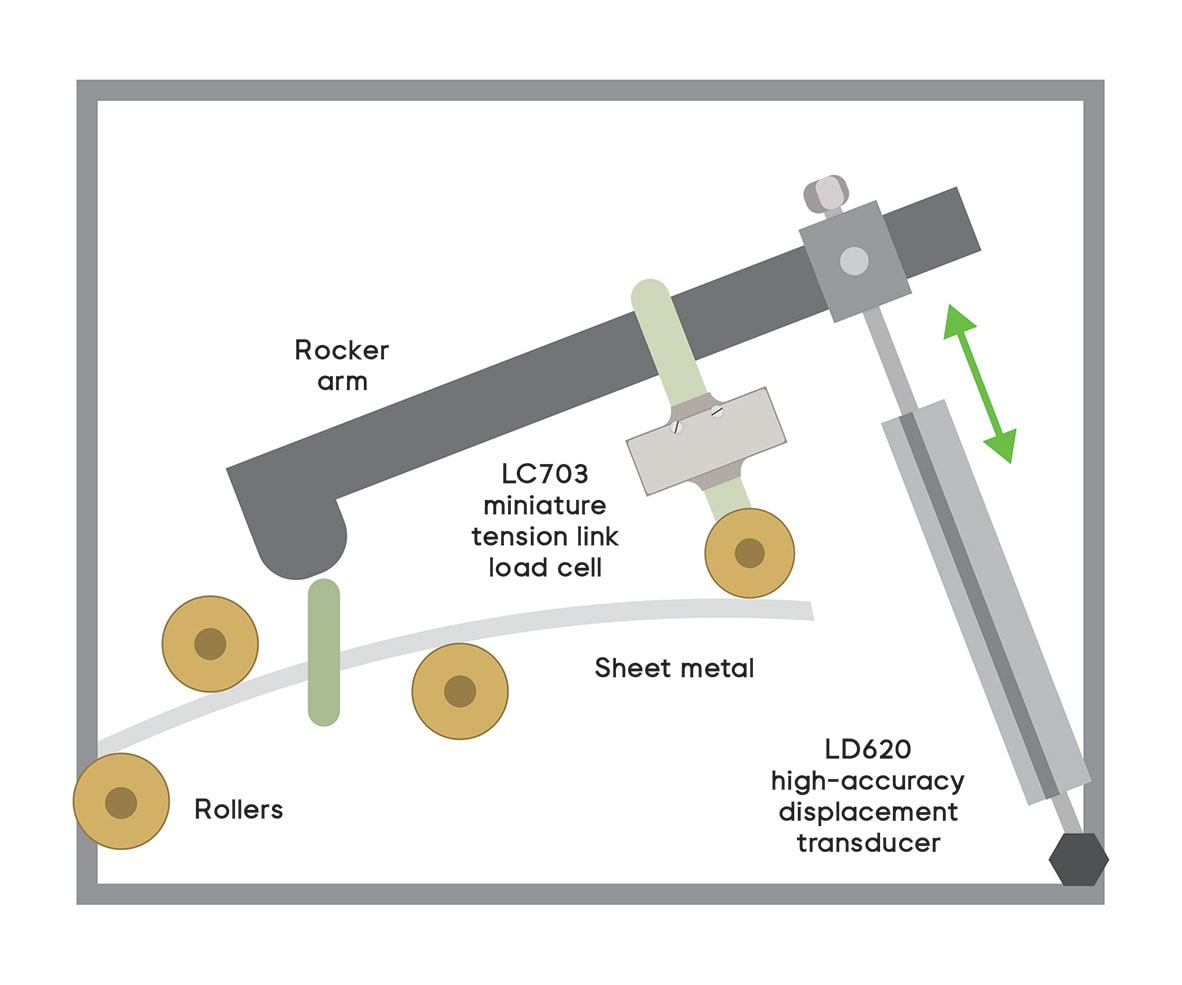

The figure above shows the schematic the sheet metal bending machine, including the placement of the load cell. The application is comprised of two products:

LC703-500: This miniature low profile tension link load cell has a rugged industrial design and 5-point calibration with 59kOhm shunt calculation data. This load cell can also provide high accuracy in either tension or compression operations.

DP25B-S: This load cell or strain guage meter is accurate, economical, and easy to program and is ideal for use with load cells. Four full digits and simplified scaling make it easy to set and read the display.

How it Works

- The sheet metal bending machine has multiple rollers which a specimen of sheet metal or other bendable material passes through.

- As the material is passing through these rollers, the rocker arm applies a force to bend the material.

- The rocker arm is also attached to the foundation of the machine. This keeps the arm moving up and down in the same motion.

- The load cell is attached to the rocker arm and measures the force used by the rocker arm to bend the material.

- A data logger, used in conjunction with the load cell, can be used to read the different force measurements.

- When the force applied consistently produces a bended material that has a uniform surface, the amount of force being applied is determined to be correct.

Results

The use of tension and compression load cell in this application allowed the customer to accurately determine how much force is optimal for repeatable results of a uniform surface finish while bending sheet metal.

Pro Tip

In applications, such as this one, where there is an axial load and the need to measure bending forces, it is preferable to use a load cell with tension and compression measurement.